In our last blog post, we talked about the global problem of counterfeit cosmetics. Today, we’re talking about who investigates counterfeit cosmetics products, starting with how cosmetics are regulated in the United States and the EU.

Regulation of cosmetics products varies greatly from country to country, so our discussion today should not be taken as an overview of what to expect everywhere cosmetics are sold. Enforcement of laws and the actions authorities take to target counterfeits also vary.

What is universal, however, is that the cosmetics industry faces unique challenges with consumer safety, increased consumer demand for transparency, and being targeted by counterfeiters. It’s good to know who investigates counterfeit cosmetics products and what measures you can take to be part of the solution.

Who investigates counterfeit cosmetics products: USA and EU

Counterfeit cosmetics are dangerous because the criminals who make them don’t follow regulations or standards for production. Fakes are often contaminated with “stuff” you really don’t want to think about, let alone put on your face, such as bacteria, animal and human feces, arsenic, and mercury. So, regulators keep an eye on cosmetics.

United States

In the United States, the Food and Drug Administration (FDA) is the governing body for cosmetic regulations. Cosmetics products do not require FDA approval — but they are regulated. The Federal Food, Drug, and Cosmetic Act (FD&C Act) and the Fair Packaging and Labeling Act (FPLA) explain the FDA’s requirements, restrictions, and disciplinary actions regarding cosmetics.

The FDA focuses on preventing adulteration and misbranding, mislabeling, and harmful ingredients or drugs. Adulteration refers to products or product ingredients that are not in line with FDA regulations or that have been contaminated. A misbranded product is “improperly labelled or deceptively packaged,” which could include counterfeit cosmetics products. The FDA prohibits 11 chemicals from being used in cosmetics products.

Additionally, the FDA reserves the authority to request recalls and work with the Department of Justice, Federal Bureau of Investigation (FBI), and Border Customs if any violations are found. It maintains a “Cosmetics Recalls & Alerts” page and has a searchable “Enforcement Report” database of recalled products.

The European Union

Cosmetics products manufactured in and imported to Europe are regulated under the EU Cosmetic Regulation. Like the FDA, the EU regulates ingredients and labeling; generally, however, the regulations are broader and more precisely defined.

For example, more than 1,300 substances (e.g., chemicals, colorants, and preservatives) are banned from cosmetic use, and hundreds more are permitted only under certain conditions. The regulations also mandate Good Manufacturing Practices (GMP), whereas the FDA only suggests GMP as “guidelines for effective self-inspection.”

Furthermore, the EU requires significant product documentation. Every cosmetics company must have a “responsible person” for every product they make. This person is responsible for ensuring products are safe and comply with regulations, and must submit a cosmetics product notification through an online portal before a product can be sold.

The responsible person must also create a product information file that includes the name, description, and nature of the product; description of the manufacturing methods; statement of compliance with regulations and GMP; a product safety report; and data about animal testing, if any. They must also assemble a product safety report that contains product safety information and a product safety assessment.

Do consumers have a role?

Yes, and it begins with vigilance with prices, packaging, and product quality:

- Prices: If the price is too good to be true or just noticeably cheaper than the last time you bought it, there’s a good chance it’s a fake.

- Packaging: The printing might look shoddy or the colors might seem off. There might not be a barcode. There might not be packaging at all, and the products might be offered in bulk.

- Product: If the consistency or texture seem different, it’s likely a fake

In the United States, consumers can “report suspicions concerning the manufacture or sale of counterfeit or pirated goods” to the FBI. For suspected counterfeit cosmetics products seen online, consumers can contact the FBI Internet Fraud Complaint Center. The FBI has also partnered with the National Intellectual Property Rights Coordination Center to create a tip line where consumers can report products they suspect to be fake.

In the EU, consumers are encouraged to contact their local authorities about counterfeit cosmetics products. Depending on the nature of the situation, the authorities might investigate themselves or contact the appropriate investigative body, which could include Europol. The United Kingdom has Action Fraud, an online reporting tool for fraud and cybercrime.

Consumers should also be aware of what brands are doing to combat counterfeits and consumer engagement programs that encourage people to report suspicious products.

Final thoughts

If you really want to drill down into the U.S. and EU regulations, download our “Global Cosmetics Market” white paper today. It also has a section about regulations in Singapore, plus more information about counterfeit cosmetics products.

In “Top Supply Chain Trends of 2021,” we posed some important questions companies should ask themselves as we move toward what is likely to be another challenging year for supply chains. Many of those questions, listed below, fit perfectly with what we talked about today — regulations, counterfeits, brand protection, consumer engagement.

Your supply chain is where all of these concerns converge. Which is why you should schedule a short demo of our solutions. In about 15 minutes, we can show you the basics of our Traceability System and how it transforms your supply chain into a strategic asset that will improve and protect every facet of your business.

- Are you keeping up with supply chain trends?

- Are there gaps and blind spots in your supply chain?

- Are counterfeits a problem in your industry?

- Are you doing everything you can to protect your brand?

- Are you actively reaching out to your customers to bring them closer to your brand?

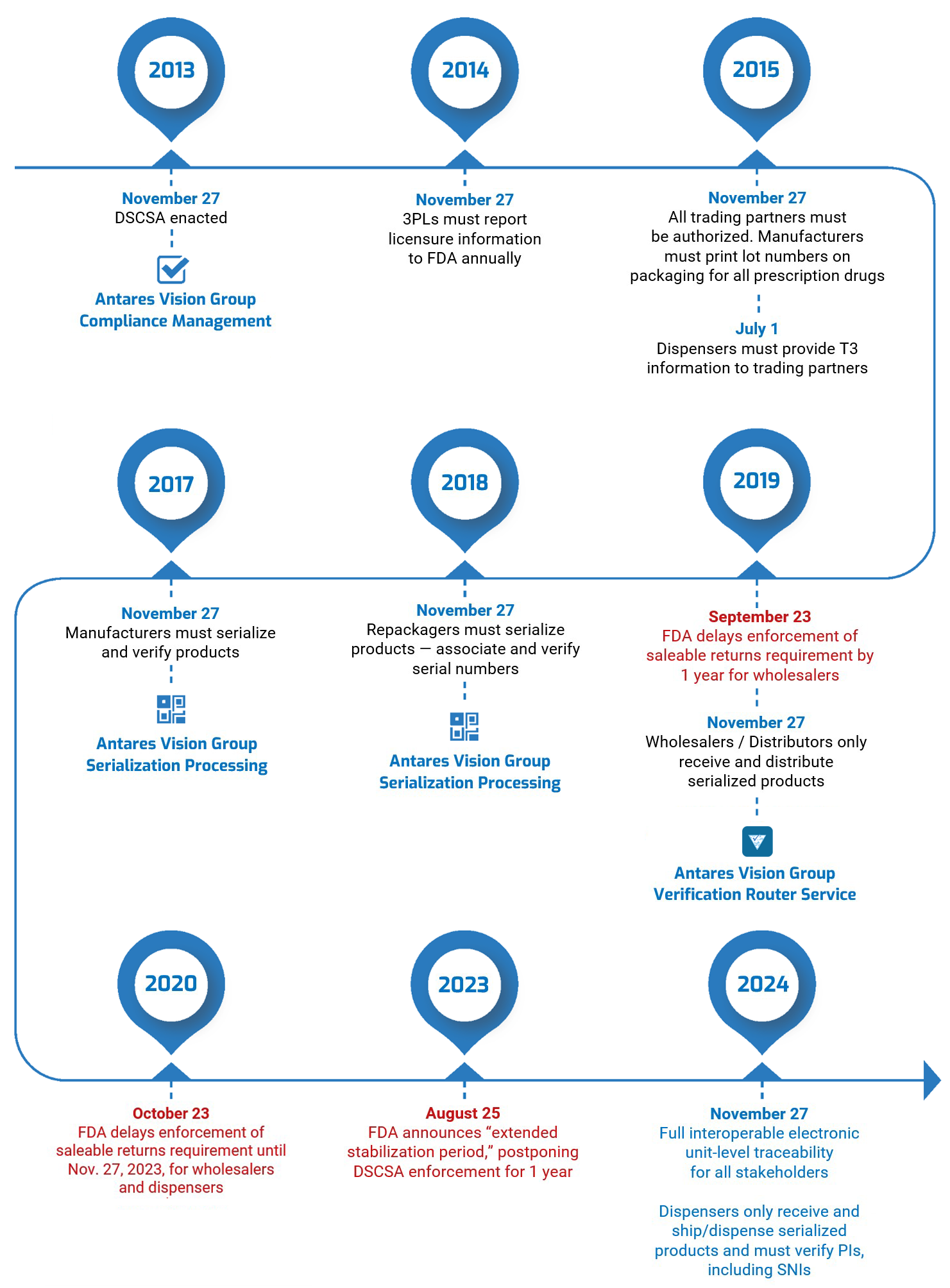

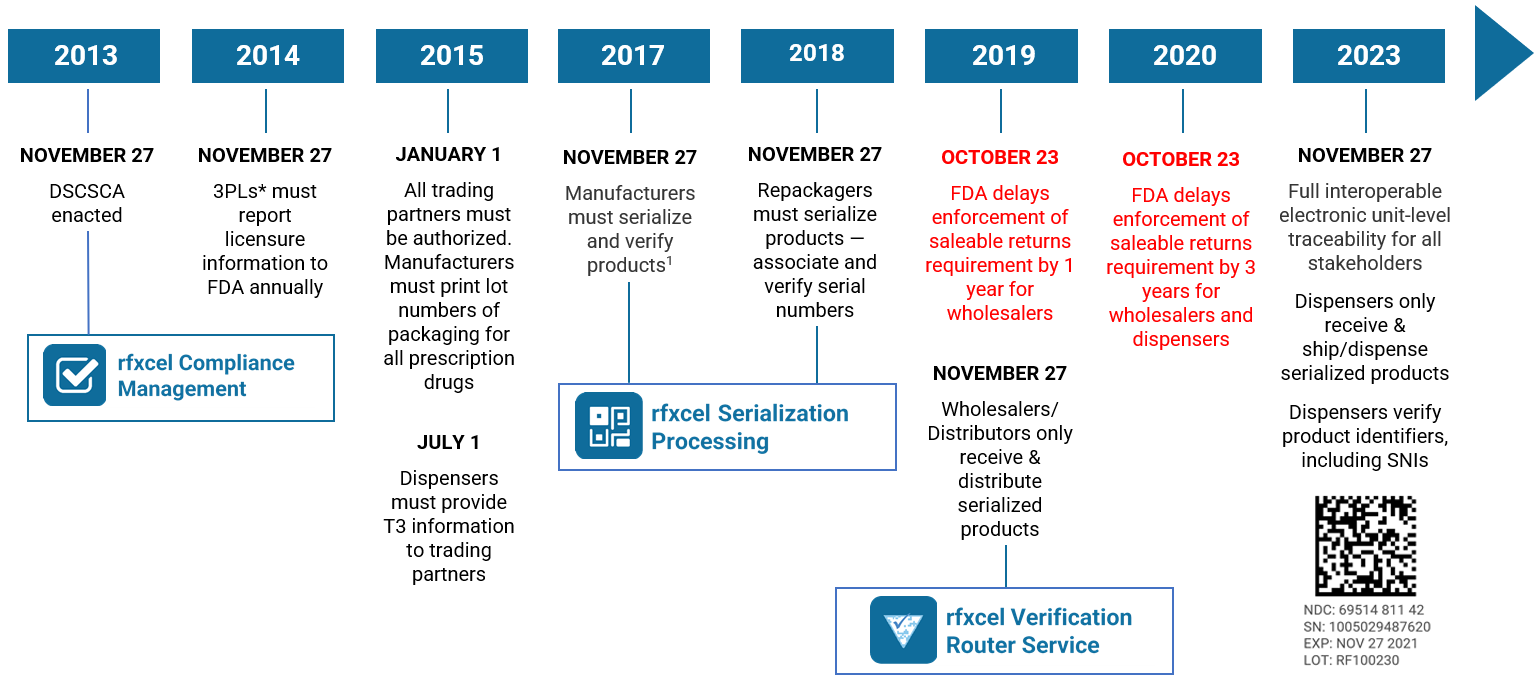

- Are there compliance deadlines on the horizon?

- Are you certain your current supply chain solutions are truly optimal?

- Are you using your supply chain as a strategic asset?