Welcome to the third and final installment of our DSCSA 2023 series. The first two parts talked about DSCSA authorized trading partners — manufacturers, wholesale distributors, repackagers, third-party logistics providers, and dispensers. If you’re not a DSCSA authorized trading partner, it will be difficult to do business in the United States, so be sure to read Part 1 and Part 2.

Today, we’re focusing on the day we’ve all been preparing for: November 27, 2023, the 10th anniversary of the DSCSA. Per Section 582(g)(1) of the DSCSA (Title II of the Drug Quality and Security Act):

“On the date that is 10 years after the date of enactment of the Drug Supply Chain Security Act … interoperable, electronic tracing of product at the package level requirements shall go into effect.”

So, in a little more than 2 years and 8 months from now, the U.S. pharmaceutical supply chain will be fully serialized. Let’s take a closer look at what this means for the pharma industry and its authorized trading partners.

A quick clarification

This blog post looks at “the letter of the law” — the language in Section 582(g)(1) that lays out six requirements for DSCSA 2023.

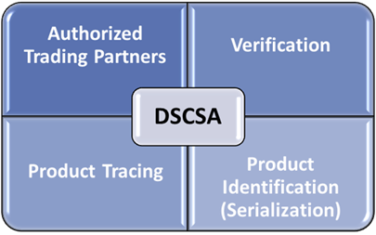

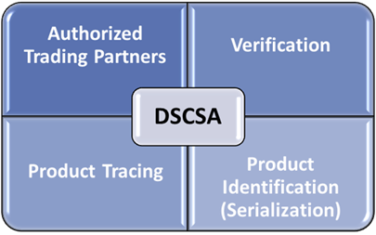

For its part, the pharma industry has tended to see the DSCSA as having four pillars, as illustrated below. These pillars encompass the six requirements we’re talking about today.

Our own Herb Wong, VP of marketing and strategic initiatives, recently hosted a webinar about DSCSA 2023 readiness that included an overview of the four pillars. It’s a great follow-up to what you’ll read below and a valuable resource for every pharma supply chain stakeholder. If you missed it or want to watch it again, Herb’s webinar is here.

DSCSA 2023: six key requirements

To date, the DSCSA has focused on lot-level traceability, or exchanging information about every package of medication so supply chain stakeholders can see exactly where each has been. DSCSA 2023 is all about complete unit-level serialization through the use of product identifiers, meaning stakeholders will have to electronically track products at the individual package level. Here are the six requirements for DSCSA 2023 laid out in Section 582(g)(1):

Authorized trading partners must exchange transaction information (TI) and a transaction statement (TS) in a secure, interoperable, electronic manner.

TI includes the product name; its strength and dosage form; its National Drug Code; container size and number of containers; lot number; transaction date; shipment date; and the name and address of the businesses from which and to which ownership is being transferred. The TS is an attestation by the business transferring ownership of the product that it has complied with the DSCSA.

Trading partners must maintain all transaction data for 6 years.

The law requires the standards for interoperable exchange of TI to “comply with a form and format developed by a widely recognized international standards development organization.” Right now, EPCIS 4 (Electronic Product Code Information Services) is the only standard that meets this requirement; however, the industry is investigating alternatives.

TI must include the product identifier (PI) at the package level for each package included in the transaction.

The upshot of this requirement is unit-level traceability (i.e., serialization). A PI is a standardized graphic that contains the product’s standardized numerical identifier (SNI), a lot number, and an expiration date. The SNI comprises two data points: the National Drug Code and a unique alphanumeric serial number. PIs must be human- and machine-readable.

Authorized trading partners must have systems and processes to verify products at the package level, including the SNI.

According to the definition in Section 581 of the DSCSA, “verification” or “verify” means determining if the PI “affixed to, or imprinted upon, a package or homogeneous case corresponds to the SNI or lot number and expiration assigned to the product by the manufacturer or the repackager.”

Authorized trading partners must have the systems and processes to promptly respond with the TI and TS for a product upon a request by the Secretary (or other appropriate federal or state official) in the event of a recall or for the purposes of investigating a suspect or illegitimate product.

The “Secretary” here is the commissioner of the U.S. Food and Drug Administration (FDA). Suspect and illegitimate products include drugs that may be counterfeit, diverted, stolen, intentionally adulterated, or unfit for distribution.

This requirement dovetails with the FDA’s push for modernization of the U.S. food supply chain, including recall processes.

Authorized trading partners must have the systems and processes necessary to promptly facilitate gathering the information necessary to produce the TI for each transaction going back to the manufacturer.

This requirement is similar to No. 4 in that authorized trading partners must provide this information to the FDA commissioner or other federal or state officials; however, goes a step further by adding trading partners. The law says these systems and processes

“shall be required in the event of a request by an authorized trading partner, in a secure manner that ensures the protection of confidential commercial information and trade secrets, for purposes of investigating a suspect product or assisting the Secretary (or other appropriate Federal or State official) with a request described in clause.”

Each person accepting a saleable return must have systems and processes in place to allow acceptance the product(s). Furthermore, they may accept saleable returns only if they can associate the returned product(s) with its TI and TS.

This has to do with the DSCSA saleable returns verification requirement and the Verification Router Service (VRS). Supply chain stakeholders must verify saleable returns before they can be reintroduced to the supply chain; they do this by verifying the drug’s PI. The VRS is the system they use to rapidly verify PIs.

rfxcel is the industry leader in the VRS. We led an FDA-approved pilot to extend testing of the VRS and continue to focus on making it ready for DSCSA 2023. Here a few of our resources to answer any questions you may have:

Final thoughts

As we said in Part 1, we’ve been covering the DSCSA for a long, long time. We’ve done webinars, written white papers, and been active in industry initiatives, particularly the VRS and the Open Credentialing Initiative (OCI) to meet the requirements for DSCSA authorized trading partners.

We’ve also been helping pharma companies comply with the DSCSA and other pharma regulations around the world. From our rfxcel Serialization Processing and Compliance Management solutions to the full-scale power of our rfxcel Traceability System, we ensure compliance no matter your role in the supply chain.

So contact us with your questions about DSCSA 2023 or the DSCSA in general. Our supply chain experts can give you a short demonstration of our solutions, share their insights and knowledge, and work with you to ensure you’re compliant today, tomorrow — always.