As we said in our post about wine supply chain trends, it’s definitely not a Dry January in our blog. Today’s topic: the digital wine supply chain.

First, though, we’re excited about exhibiting at the Unified Wine and Grape Symposium next week. Head over to our sign-up page. We have some complimentary passes available (on a first-come basis) and we’ll be giving away a few bottles of fine Italian wine at Booth 807! Sign up and visit us at the show!

Now, on to the digital wine supply chain.

What are the benefits of a digital wine supply chain?

If you follow our blog (and we know you do), you know we’ve been talking about the digital supply chain for years. For us, digitization isn’t a fad or a trend; it is the No. 1 most important “thing” you can do for your business.

In broad terms, the benefits of building a digital wine supply chain are visibility, traceability, and transparency; sustainability; optimized efficiency and productivity; and creating value and enabling new business models.

It’s important to note that visibility, traceability, and transparency make all the other benefits possible. This “trifecta” in a digital wine supply chain enables longevity, brand strength, innovation, and compliance.

Digital wine supply chain trends

We’re not ranking these digital wine supply chain trends, just noting some of the most important and prominent technologies that are driving the industry. This is also a very high-level summary, as getting into granular details is far beyond the scope of our blog. If you have any questions or want more information, contact us!

Furthermore, these technologies are important in every supply chain. It doesn’t matter what your business is: a digital supply chain is your most important strategic asset.

Blockchain

If you had to describe blockchain in one word, it would probably be “security.” Specifically, it’s about forwarding (i.e., sharing, utilizing) encrypted data that’s virtually impossible to corrupt, alter, or otherwise modify. For details about what it is and how it works, download our “Blockchain-Based Supply Chain Traceability” white paper.

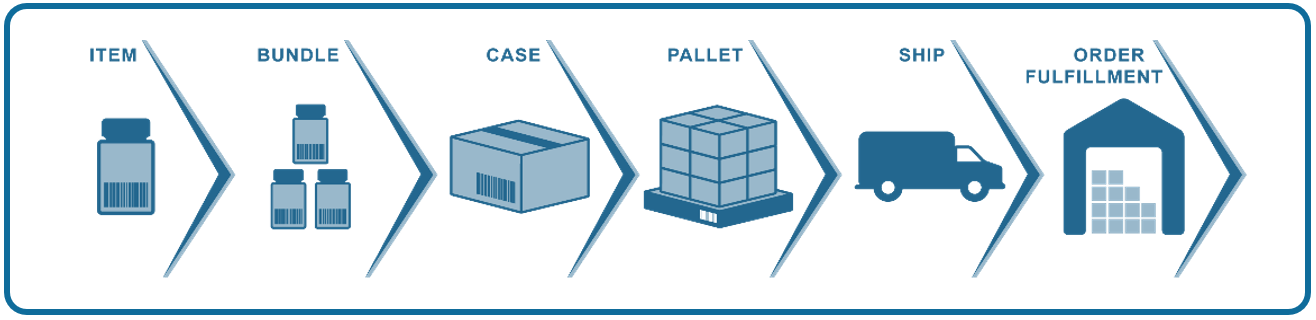

For the digital wine supply chain, blockchain’s primary appeal — as you might have guessed — concerns visibility, traceability, and transparency. Put simply, it’s a powerful tool to verify everything in your supply chain, from the vineyard to distribution to final sale to the person who will be pouring your wine into a glass. It makes traceability accessible and verifiable for everyone in the chain (e.g., your trading partners).

Blockchain has other applications, such automatically verifying, validating, and enforcing contracts. These “smart contracts” can be implemented throughout the digital wine supply chain, to set up and confirm deliveries and pay suppliers, for example. There’s even been some buzz about non-fungible tokens (NFTs) in the wine industry.

Adoption of blockchain is far, far from universal. People still don’t fully understand what it is, how it works, and the value it can bring. However, the consensus seems to be that it will blossom and proliferate during the 2020s. Nowadays, data is king; blockchain safeguards data, so keep it on your radar.

Internet of Things (IoT)

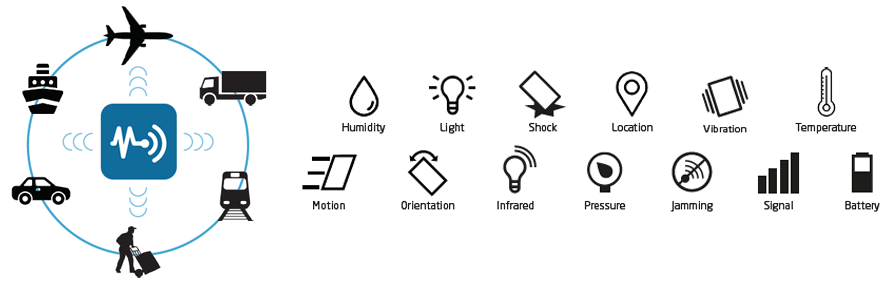

IoT technology puts you everywhere your supply chain goes. It’s the heart of real-time data collection, monitoring, adjusting, risk mitigation, and brand empowerment.

For the wine industry, this means using sensors to cultivate “smart vineyards” and build a supply chain with end-to-end visibility, traceability, and transparency. (Are you detecting a theme?) For example, IoT-enabled sensors can be buried in soil, embedded in vines, or hung in leaves to monitor environmental conditions, collect data, forecast weather conditions, reduce risks during harvesting, and improve productivity.

IoT also promotes sustainability, including water and soil conservation and lowering/eliminating pesticides; combined with satellite imaging, these capabilities safeguard vineyards and promote sustainability.

IoT has applications in every facet of the wine the supply chain. The upshot is data. Lots and lots of data. Collected and transmitted in real time, the data tells you exactly what’s happening in every part of your operations on land, air, and sea.

E-labels and e-certificates

Electronic labels, or e-labels, make life easier for everyone: You, your employees, your trading partners, regulators, packaging designers, graphic designers, and your customers. They are foundational to the digital wine supply chain. And because they replace multiple paper labels, e-labels are better for the environment and promote sustainability.

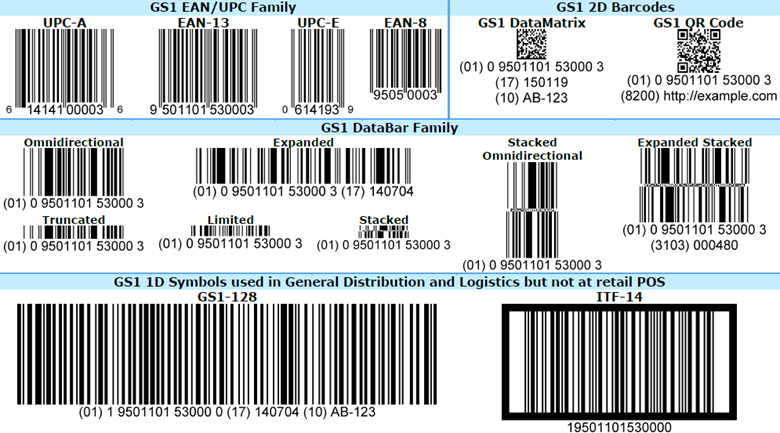

DataMatrix codes and QR codes are examples of e-labels. Essentially, they can be “loaded” with information about ingredients, product provenance, traceability data, compliance data — virtually anything. They can also link to social media, websites, apps, rewards programs, and special content such as videos. E-labels are an all-in-one solution for every member of the digital wine supply chain.

Importantly, e-labels are powerful tools to fight fraud and counterfeits, problems that have a huge negative impact on the wine industry. Full traceability data, accessible with a single scan by a supply chain partner or a consumer in a store, proves a that a bottle of wine is genuine. E-labels are critical to our trifecta of traceability, transparency, and visibility.

A good case study is the EU’s “U-label” digital platform, which allows wine and spirts producers to easily create e-labels (in this case QR codes) and give consumers product information in their native language. It’s a collaborative effort of the Comité Européen des Entreprises Vins (CEEV), the association representing the European wine industry, and SpiritsEUROPE, whose mission is to “represent, defend and promote the European spirits sector and help members achieve sustainable business growth.”

For a deep dive on QR codes, DataMatrix codes, and other barcodes, read our “Understanding GS1 Barcodes in the Global Supply Chain” blog post.

Electronic certificates are similar to e-labels. They too are “loaded” with data that prove a product meets certain requirements and certifies key information such as origin, import-export status, tax status, and sanitary/phytosanitary compliance.

In the wine industry, common certificates include certificates of origin, free sale certificates, quality certificates, organic certificates, and environmental certificates/certifications. However, the industry has not established standards for e-certificates and to a large degree still relies on a paper-based system.

With the push for a digital wine supply chain, standard-making bodies for e-certificates should consider what certifications to include (e.g., origin, export, quality, sanitary), relevant categories of information (e.g., producer, brand, batch, Harmonized System code), and how the information will be exchanged (e.g., through central hubs).

Other things to watch in the digital wine supply chain

We’ve run out of space for now, but here are few other things to keep an eye on as the digital wine supply chain evolves.

- Artificial intelligence to manage and process data, monitor crops, make decisions about watering and fertilizing, predictive maintenance on lines, warehouse management, and distribution

- Robotics in planting, fertilizing, pruning, harvesting, and warehousing

- Geographical Information Systems (GIS) and satellite imaging for “digital cartography” to monitor land use, study the effects of climate change, conduct surveys, track diseases, generate thermal and infrared imaging

- Creating “digital assets” to leverage in brand protection and consumer engagement strategies. Note: Our upcoming articles will discuss this in detail.

Final thoughts

The wine industry has always maintained a balance between tradition and innovation. Winemakers, grapegrowers, and other stakeholders want to preserve the past while embracing current and developing technologies.

The digital wine supply chain brings the industry the best of both worlds: Technology ensures traditions endure. But technology also creates new traditions for traceability, transparency, visibility, and sustainability — the very things that, as we said at the outset, enable longevity, brand strength, innovation, and compliance.

Contact us today to learn more. And be sure to read our other articles about the wine supply chain and why your supply chain is vital for effective consumer engagement and brand protection:

- Wine Brand Protection and the Fight Against Counterfeits

- Wine Consumer Engagement: Ten Things to Know for 2022

- Wine Supply Chain Trends for 2022: Five Things to Watch

- Why We Need Wine Industry Track and Trace (2-Part Series)

- Brand Protection Strategies and Your Supply Chain

- Top Supply Chain Issues that Affect Your Brand Protection Strategy

- Top Reasons Your Supply Chain Is Key to Consumer Engagement Strategy

- Why Your Supply Chain Is Vital for Effective Consumer Engagement