It’s going to be a busy year for dairy product labeling in Russia. (If you missed our earlier overview, be sure to check it out.) In fact, it’s going to be a busy year for product labeling in Russia generally. A quick look at our blog reveals that the National Track and Trace Digital System, or Chestny ZNAK, is not relenting on its goal of transforming Russia’s supply chain by 2024:

- Russia Chestny ZNAK Bottled Drinking Water Pilot Ending Soon

- New Russian Serialization Pilot for Biologically Active Food Additives

- Russia Serialization Pilot to Combat Counterfeit Beer Set to Begin This Spring

- Russia Pharma Serialization Update: “Notification Mode” Expedites Product Circulation

But let’s stay focused on dairy product labeling, which is scheduled to commence on June 1 for two product categories, then will be phased in for two other categories later in the year.

Dairy product labeling in Russia: background

The Chestny ZNAK pilot for dairy product labeling from July 15, 2019, to December 31, 2020. The dairy supply chain has a unique configuration because Chestny ZNAK will share track and trace duties with the “Mercury” electronic veterinary certification system, which tracks animal products in Russia.

Dairy product labeling requires a DataMatrix code containing four data points: a 14-digit Global Trade Item Number (GTIN), a 13-digit serial number, a 4-digit verification key, and an expiration date.

Other dairy product labeling requirements include the following:

- Product packaging must have a blank field up to 15×15 mm to accommodate the DataMatrix code.

- Caps on PET bottles must be able to accommodate either printing or labeling with a laser.

- Manufacturers can have unusually shaped cartons or bottles tested to determine if the form factor affects dairy product labeling and scanning accuracy/reliability.

- Aggregation is required; the parent-child relationship must be maintained between the aggregation and the individual units within it.

If you want to learn more about Russian dairy product labeling, download our “Russia Chestny ZNAK and the Dairy Industry” white paper. It’s fully updated for 2021 and really drills down into the details.

While we’re at it, if you want to learn about product labeling and serialization for all of the industries regulated in Russia, download our “Overview of Chestny ZNAK Compliance for Key Industries.” This is also fully updated for 2021 and is our most comprehensive publication about Russian supply chain compliance.

The June 1 dairy labeling requirements

Mandatory dairy product labeling begins June 1 for cheeses and ice cream and other edible ice with or without cocoa. Only serialized products can be sold after this date. However, products produced or imported into Russia before June 1 may be sold until the product’s expiration date.

Companies were permitted to begin labeling these cheese and ice cream products as early as January 20, 2021. They were also allowed to transfer dairy product labeling data to the Government Information System for Marking (GIS MT), which catalogs all labeled goods in Russia’s supply chain. To transfer data to GIS MT, you must be registered with Chestny ZNAK.

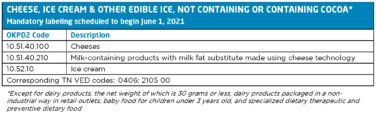

The table below shows Russia’s product classification codes (OKPD2) and the corresponding Eurasian Economic Union (EAEU) Combined Nomenclature of Foreign Economic Activity (TN VED) codes for labeling these products. This information comes from Chestny ZNAK.

Final thoughts

rfxcel is the leader in Chestny ZNAK compliance. Not just for dairy product labeling — for labeling requirements in all regulated industries. We know these regulations can be tough to decipher. To help, we have useful resources, like the stories we linked above, our Chestny ZNAK refresher course, our white papers, and our webinars.

These are great places to start, but the best way to ensure you’re prepared to comply with Russia dairy product labeling requirements is to talk with us directly. When we say we’re the leader in Russian compliance, consider our credentials:

- We’re an official integration, software, and tested solution partner with the Center for Research in Perspective Technologies (CRPT), which operates Chestny ZNAK.

- We were recently accredited as an IT company by the Ministry of Digital Development, Communications, and Mass Media.

- We’re one of the few providers with active implementations in Russia.

- We’ve tripled our workforce in Russia over the last year.

- Our Moscow-based team provides our clients, which include major global consumer goods and pharmaceutical companies, the quickest time to market while fully automating their compliance reporting.

We’ve also demonstrated that our solutions, including our signature rfxcel Traceability System (rTS), Compliance Management (rCM), and Serialization Processing (rSP), can meet the stringent Russia dairy serialization requirements and ensure you stay compliant. In fact, we had to prove this to the CRPT to be named an official partner. rTS works seamlessly with Chestny ZNAK, including a Russian-language user interface that makes integration and startup much quicker.

So contact us today learn more about how we can help you with dairy product labeling and other Chestny ZNAK compliance. No matter how far along you are in your preparations to comply, you should talk to us — even if you’re already working with another provider. Our powerful software ensures companies in any industry remain compliant with Russia’s complex regulations.