In the healthcare sector, delayed, lost, and damaged products can cause grave danger, as patients might not receive the medicines they need on time and many items are susceptible to fluctuations in environmental conditions. That’s why it’s crucial to have a reliable and robust healthcare value chain.

Let’s examine the critical role that the healthcare value chain plays. Our technologies and solutions help pharmaceutical companies, hospitals, and other healthcare stakeholders streamline and manage their entire supply chain, from procurement to distribution.

Understanding the healthcare value chain

Most may believe that the value chain and supply chain are synonymous. However, they are two different terms describing different aspects of supply logistics. The supply chain refers to the movement of goods from suppliers to customers; the value chain encompasses all activities involved in creating and delivering a product or service.

In other words, the supply chain is more about the physical movement of goods and the value chain adds value to a product, including production, marketing, and customer support after the sale. So, the healthcare value chain allows medical institutions to provide patients with the best possible care by ensuring they have the supplies and treatments they need when they need them.

What happens in a healthcare value chain?

Understanding the activities involved in the healthcare value chain is the first step in managing and streamlining its processes. We’re talking about logistics, operations, marketing and sales, and service.

Inbound logistics. The value chain is not a product-driven process, so explaining inbound logistics can be challenging. Generally, inbound logistics in a value chain refers to the quality of inventory and the management of that inventory. Value-driven inbound logistics ensures that all inventory is accounted for and is of the highest quality. This includes checking that items are not expired or damaged and meet all necessary requirements (e.g., internal quality control, standard operating procedures).

Operations. The operations stage of the healthcare value chain is where the actual product or service is produced. In this value-driven scenario, product operations and/or manufacturing aim to reduce waste and create efficiencies. This might involve automating processes, changing production methods, and improving the quality of raw materials. In healthcare, the goal of operations might be to streamline the manufacturing of drugs or medical devices.

Outbound logistics. Like inbound logistics, outbound logistics in a value chain should strive to ensure that a product or service reaches the customer in the best possible condition and in a timely manner. In healthcare, this means making sure that patients receive their supplies and treatments when they need them, as well as ensuring products are safe and legitimate.

It’s also important to note that outbound logistics isn’t just about the distribution of supplies outside a warehouse. It also concerns how medical institutions distribute supplies internally. This is important to consider when managing a hospital or other medical facility.

Marketing and sales. Marketing and sales in the healthcare value chain focus on creating demand for a product or service. Traditionally, this includes advertising, promotions, and other marketing initiatives. In a value-driven context, marketing and sales are strategically designed to go beyond a one-time sale to create long-term relationships with customers. There are numerous ways to do this, ranging from creating educational materials for patients and promoting online services to partnering with insurance providers.

Service. The service stage of the healthcare value chain is where post-sales activities occur, such as continuing customer support, repairs, and maintenance. Value-driven service helps maintain customer satisfaction with the product or service and helps ensure their needs are being met. Customer loyalty programs, follow-up communications, and offering extended warranties are common examples.

The healthcare value chain in numbers

Now that we’ve summarized the different stages of the healthcare value chain, let’s look at some numbers that help illustrate why these processes are so vital to the healthcare industry.

One 2019 report found that clinicians devote about 17 percent of their time to logistics and storage management activities. This affects their productivity and the quality of care they can provide.

The report also found that more than 4,500 different medical devices and products are recalled every year — and 10 percent of these have the potential to cause harm or death. One study published by the well-known consulting outfit McKinsey & Company reported that the “costs of a single non-routine quality event, like a major recall, have been as high as $600 [million] in medical device companies.”

The long-term business benefits of an effective healthcare value chain

An effective healthcare value chain creates benefits beyond improving quality of care and securing patient safety and satisfaction. It creates business benefits, including:

Improved profitability. An effective healthcare value chain can boost a bottom line by improving supply systems, reducing waste, and creating efficiencies across healthcare systems.

Promoting innovation. Less waste and more efficient systems mean savvy companies can devote more resources to R&D that can lead to innovation in all realms, including the development of new treatments or therapies and better manufacturing and distribution schemes.

Helping meet business goals. An effective healthcare value chain contributes to business success by reducing waste, increasing efficiencies, and promoting innovation. It also helps businesses connect with customers and build brand loyalty.

Final thoughts

What’s the main takeaway from this overview of the healthcare value chain? Establishing an agile and robust value chain is essential to success in the healthcare industry — in every industry.

We’ve specialized in creating software solutions for the healthcare value chain (and the healthcare supply chain) for almost 20 years. Our No. 1 priority is to help businesses optimize their operations and improve the quality of the products they manufacture and deliver to consumers.

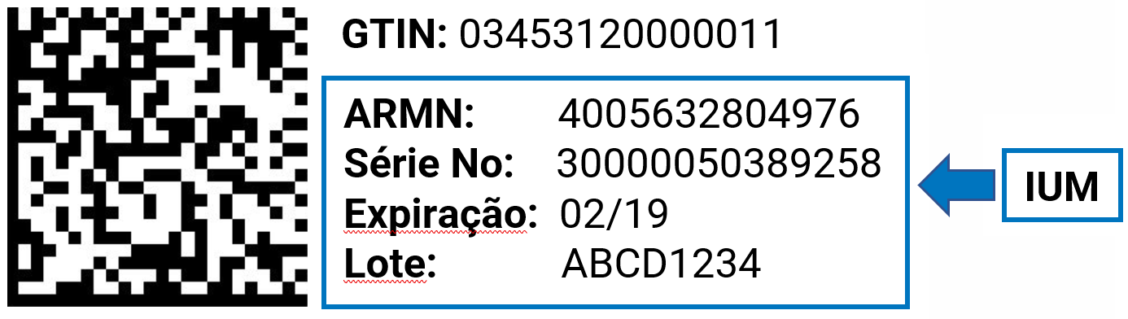

For the healthcare and pharmaceutical industries, this means providing a digital traceability platform that helps ensure your devices and medications are safe, are transported following proper protocols (e.g., routes and environmental parameters), are delivered on time, and meet all regulatory requirements. It means real-time data and visibility into every aspect of your operations from virtually any location in the world.

rfxcel and Antares Vision Group understand the healthcare value chain, its complexities, and how to optimize it for patient security, customer satisfaction, and business success. Contact us today to schedule a short demo of our solutions. Our experts will answer your questions and show you why major global healthcare and pharmaceutical companies rely on our technology to secure and improve their operations.