Over the years, there have been countless instances of counterfeit drugs entering the supply chain. This is problematic, as counterfeit drugs put consumers at risk, even causing injury and death. To help resolve this issue, many stringent compliance regulatory systems have been put in place for the pharmaceutical industry and other industries. One example is traceability and serialization, which includes aggregation.

What is aggregation?

Aggregation creates and maintains a parent-child relationship for the packaging levels and the product owner’s information. It creates the parent-child relationship by associating the aggregated unit, which is the parent, with each carton’s various serial numbers. For example, a basic mapping of aggregation may look like this:

Unit-level pack aggregations (lowest level) → bundle pack aggregation → case aggregation → pallet aggregation (highest level).

Aggregation increases safety and efficiency in the pharmaceutical industry and is an essential part of serialization in the supply chain. Aggregation helps track a package throughout its entire journey – from the time it is packaged to the moment it reaches the consumer.

Why is aggregation necessary in supply chain management?

Increases traceability and transparency

Aggregation makes it much easier to trace products through each step of the supply chain. It also makes it easier to “interpret” what’s in your supply chain. This increases traceability and transparency, which offers a variety of benefits, including:

- Increased trust from stakeholders

- Important supply chain data

- Increased resiliency during a crisis, such as a pandemic, a recall, political unrest, or a natural disaster

Increases efficiency

Because aggregation and parent-child relationships eliminate the need to scan individual units, they create a quicker, more efficient flow in your supply chain. Furthermore, they’ll make your supply chain more accurate because there are fewer opportunities to make mistakes. Last, increased efficiency means saving on costs and time, as less scanning helps companies take care of returns and recalls more quickly.

To further mitigate opportunities for mistakes, you can always consider tools like automated supply chain management systems to stay in sync with capabilities and production needs all the way down the supply chain.

Increases safety

With aggregation and the resulting parent-child relationships, safety is increased in your supply chain. Because aggregation increases accuracy and transparency, the risk of accidentally selling counterfeit products goes down. This means customers can trust that your product is authentic and do not have to fear any harm that can come from these counterfeit products.

Final thoughts

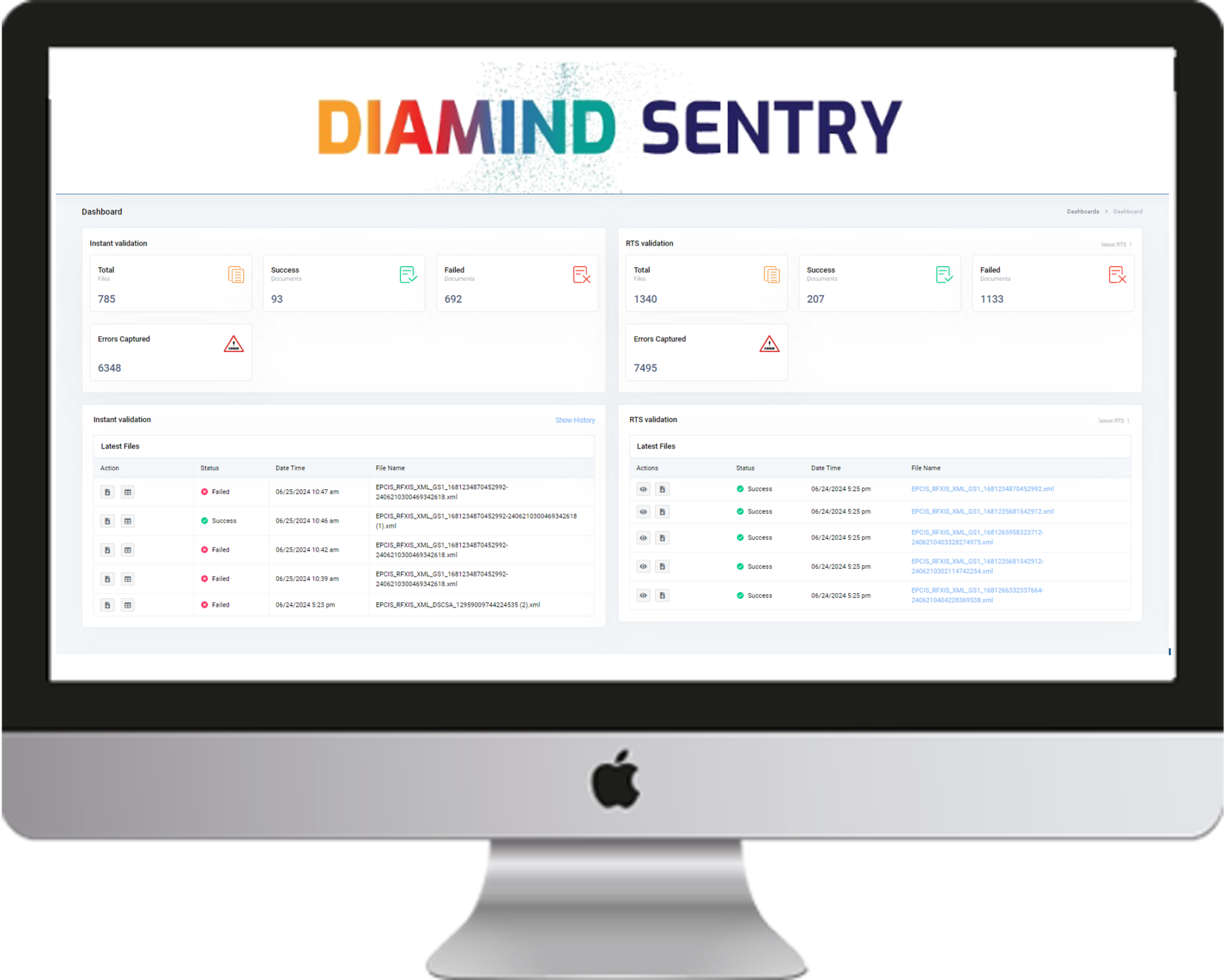

Working with a track and trace company helps improve aggregation within your supply chain, which, in turn, increases efficiency, transparency and safety. By making these improvements to your supply chain, you’ll help prevent counterfeit drugs from entering it. Contact us today to learn how our track and trace system, rfxcel Traceability System (rTS), can simplify and accelerate your processes with aggregation today.